For precise and efficient material separation in production, quality control, ...

Read More

WE CONNECT AUTOMATION WITH THE HIGHEST PRECISION

Discover the benefits of automation for your business with our innovative solutions.

Dockweiler Industrial Automation

Welcome to DOCKWEILER INDUSTRIAL AUTOMATION. Within the Dockweiler Group, we specialise in the automation of industrial production and the manufacture of systems for material testing. The motivated team at DOCKWEILER INDUSTRIAL AUTOMATION currently consists of more than 10 specialists and has 30 years of experience. Worldwide, the Dockweiler Group has more than 780 employees in over 10 countries.

News

Dockweiler Industrial Automation receives research grant and BSFZ seal

Dockweiler Industrial Automation has been officially recognized for its innovative ...

Read Moreportfolio

Automation technology

More efficiency, accuracy, consistent quality and cost savings: Experience the future of manufacturing with automation systems. Let’s plan together how automation can move your business forward.

Component manufacturing

Expand your production capacity with contract and make-to-order manufacturing without large investments. Contact us to learn more about our services to help you optimize your workflow.

Materials testing

Automation of destructive materials

testing – with more speed, accuracy and cost savings.

We will be happy to show you how you can benefit from our solutions.

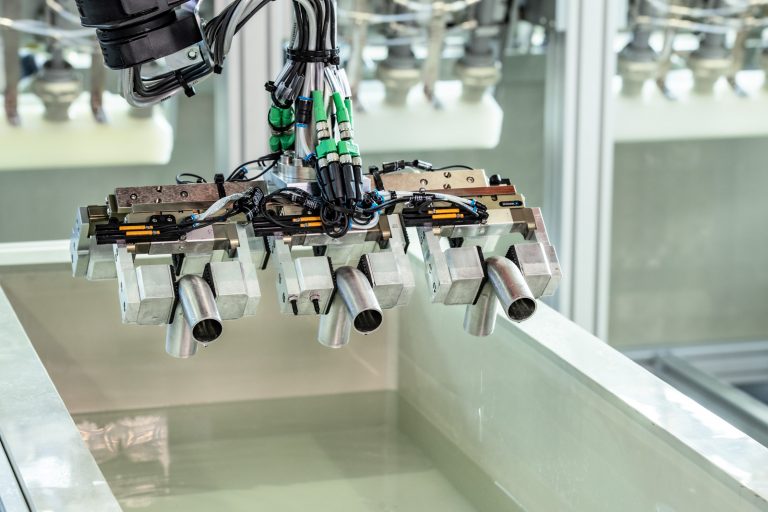

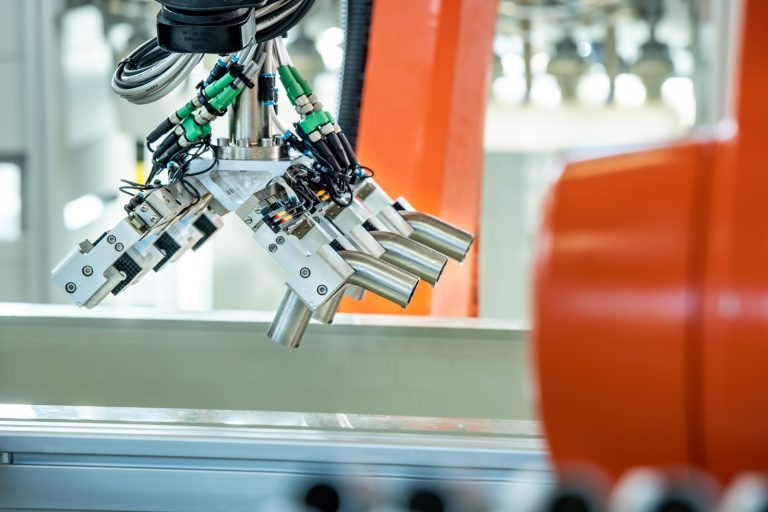

AUTOMATION SYSTEMS FOR INDUSTRY

We are specialists in the design of state-of-the-art and comprehensive solutions for the automation of production processes. Material feeding plays an important role in this.

We replace manual processes with the sensible use of robotics. In close cooperation with our customers, we develop, design and produce customized assembly lines, machines and systems with which you increase product quality, remain competitive and improve your efficiency.

We support our customers right from the development phase of their products and use only the highest quality components to ensure reliable production.

Automation solution with robotics:

Example metalworking and surface treatment

Automated material feeding and removal can significantly increase the quality and quantity of what was previously a manual process.

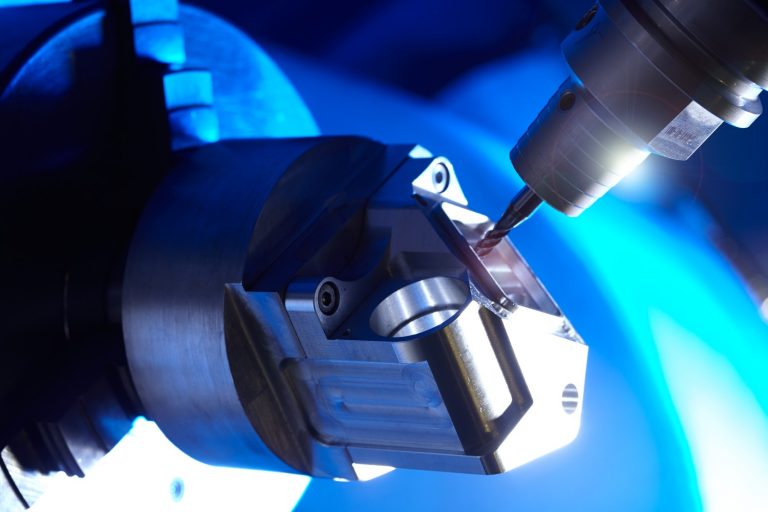

EFFICIENT COMPONENT MANUFACTURING AND MODULES FOR AUTOMATION TECHNOLOGY

Concentrate on your core business: The production of individual components is an important part of our range of services. Benefit from our many years of experience in classic mechanical engineering. We manufacture components according to your wishes and drawings.

With modern CNC technology and qualified personnel, we deliver high-quality results quickly and reliably. Contact us to learn more about our services to help you optimize your workflow.

- Mechanical engineering

- Medical technology

- Measurement and control technology

- Plant engineering

- Special machine construction

Mechanical engineering:

Your partner for development and precision optimization!

The origin of Dockweiler Industrial Automation lies in metalworking as an engineering discipline with scientific reference to classical physics and mechanics. We work together with our customers on the idea, draft, construction and design as well as the optimization of machines of all kinds and their components. The focus is on the creation of customer-oriented solutions to problems in mechanical engineering as well as on consulting and supporting our customers in the fulfillment of their orders.

For example, for the benefit of our customers, we also deal with the objectives and methods that must be observed in the design of technical equipment by DIN standards. We plan and design their technical components on the computer using CAD programs. The CAD files generated in the process can then be subjected to simulation and manufactured by a CNC machine.

One of our specialties is the production of components, at the same time we answer questions about how to produce a component with a certain tolerance and how to produce it in the most cost-effective way.

Medical technology:

High quality standards for your products!

The future-oriented medical technology industry is a high-tech, innovative and interdisciplinary field of work. Where medical professionals conduct clinical research, Dockweiler Industrial Automation engineers support our customers in translating these research findings into new medical technology products and processes. In the process, many well-known manufacturers rely on the high Dockweiler Industrial Automation quality standard for the production of individual and series parts.

Together with our customers, we optimize design and components. Dockweiler Industrial Automation quality targets are defined along the entire value chain and for all workplaces. In this way, we ensure consistently high quality on a permanent basis. Furthermore, we use every suggestion to further improve our processes.

Measurement and control technology:

We support you in optimizing your products!

Here, we basically work according to the Dockweiler Industrial Automation principle of measurement and control technology. First, an actual value is determined by means of measurement technology, compared with a specified reference value or setpoint, and the reference variable is influenced by the controller in such a way that the deviation between the actual value and the setpoint is minimized. Thereby, the control is basically a combination of a measurement – recording of a value – and the control of a system – output of a value – depending on the respective specifications.

This simple and clear structuring of the field of measurement and control technology enables us to cover a wide range of applications. In addition to the production of individual and series parts, Dockweiler Industrial Automation activities in the field of measurement and control technology focus on product optimization. Furthermore, we advise customers on casting optimization and support our business partners from design to the finished product.

Plant engineering:

Our Dockweiler Industrial Automation maxim, we deliver complete!

For Dockweiler Industrial Automation, typical customer orders come from the following areas of plant engineering: process engineering, energy and supply engineering, production engineering, mechanical engineering and electrical engineering. Here, Dockweiler Industrial Automation combines all technical components in process engineering plant construction into a complete system with precisely defined tasks.

The customer-specific tasks represent central framework conditions for Dockweiler Industrial Automation and result from the overall process that is to be realized with the system.

The approach practiced by Dockweiler Industrial Automation starts with an examination of the individual steps of each process and then questions its controllability. Once these prerequisites have been ensured for all sub-processes, the necessary equipment design can be developed. The complete plant concept is then created by interconnecting, adapting and optimizing the technical components.

Dockweiler Industrial Automation also guarantees support after the customer has commissioned the plant. In addition to assemblies and individual parts, it is primarily spare parts as well as purchased parts that are supplied quickly and reliably by us during this phase.

Special machine construction:

From the design to the finished machine!

Dockweiler Industrial Automation special machine construction characterizes a branch of mechanical engineering in which innovative special machines with a unique character are manufactured. In contrast to series machines that can be bought ‚off the peg‘, special machines are specially designed and manufactured by Dockweiler Industrial Automation according to customer requirements. In this respect, Dockweiler Industrial Automation covers the entire spectrum from the completely new development of a machine to more or less extensive customer-specific adaptations. These special machines are therefore one-offs or small series that are only produced in small quantities by Dockweiler Industrial Automation.

The direct communication we maintain is a central Dockweiler Industrial Automation success factor, especially in special machine construction. Furthermore, the immediate exchange of information ensures that our partners and customers are provided with the right information transparently and quickly. Our employees do not answer questions schematically, but against the background of the respective company-specific problem. Personal contact is important to us.

SYSTEMS FOR DESTRUCTIVE MATERIALS TESTING

Materials testing of components requires the highest degree of accuracy. The procedures involve different stresses and loads that vary in type and scope. At the same time, any number of repetitions under identical conditions must be guaranteed.

Our automation systems ensure maximum precision and efficiency: from material feeding to automatic material testing. Our years of experience enable us to master even the most difficult challenges.

Automated notch bending machine

© Zwick Roell

YOUR CONTACT PERSONS

Oliver Ernst

Managing director

- +49 7232 80979-00

- o.ernst@dockweiler-ia.com

Otmar Berg

Construction /

Mech. CAD Design

- +49 7232 80979-13

- o.berg@dockweiler-ia.com

Jochen Frentzel

Software

- +49 7232 80979-11

- j.frentzel@dockweiler-ia.com

Johann Petri

Plant Manager

- +49 7232 80979-20

- j.petri@dockweiler-ia.com

Ralf Gaiser

Work preparation

- +49 7232 80979-24

- r.gaiser@dockweiler-ia.com

Purchasing

Invoices

Contact

Dockweiler Industrial Automation GmbH

A company of the Dockweiler Group

Theodor-Heuss-Straße 13

D-75203 Königsbach-Stein

- +49 7232 80979-00

The BSFZ seal is a recognized proof of our innovative strength and commitment to research and development.